Selecting and purchasing mop hardware can be a time consuming task and a significant investment. Major considerations need to be evaluated including the ability to do the job properly, operator ergonomics, cost, quality, and product life expectancy. Buying quality mopping products provides better cleaning performance and longer life of the hardware. Often not considered is the proper maintenance and storage of the mopping hardware.

Hardware Maintenance Extends Life of Mopping Systems

Category: General Info

Preventive Maintenance

Proper maintenance extends the life of the hardware, reduces possible cross-contamination as well as down time in manufacturing. Just like production equipment, mop hardware should have periodic maintenance performed in order to keep it working properly. Items to include in a preventive care and maintenance program would be wringers, trolleys, handles, head frames, and buckets. These items are usually not considered capital expenses but can have significant value.

Stainless steel materials with electropolished surfaces enhance chemical resistance but should not be considered impervious to chemical solutions. Sterilization by chemical (cold sterilization) or by autoclave along with standard scratches and dents that occur during use can take a toll on these systems affecting contamination control and possibly lead to areas that harbor microorganisms. It is imperative to properly clean and remove chemical residues and allow the hardware to dry between uses.

When Remediation is Needed

Constant use in manufacturing environments along with extended exposure to disinfectants and other chemicals will cause rouging over time. These areas of weakness can harbor microbiologic contamination resulting in product loss and warning letters from inspectors. If proper cleaning is neglected, this rouge will develop into rust. These conditions can be corrected by using fine diamond grit abrasives to remove contaminants from surfaces.

Proper Storage

Hardware storage areas are commonly overlooked when designing a clean room space. Obtaining a dedicated space to store mop hardware will result in improved operating efficiency as well as extend product life span. This provides workers with a place to maintain mop systems, hang the parts between uses as well as keep hardware from falling, being scratched or dented. This storage area should have access to process water, a drain, and a rack system appropriately sized for the hardware used at that location.

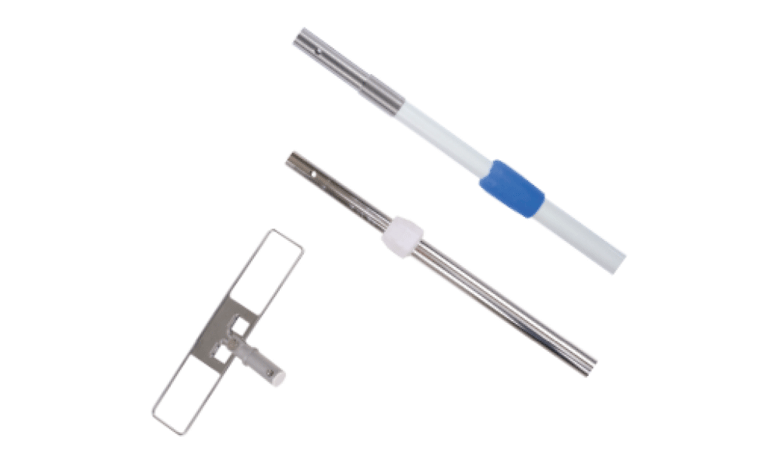

Hardware Replacement Parts

Replacement parts should be readily available. Common replacement parts include casters, tightening collars for telescoping handles, pressure bars/springs for wringers, and pressure buttons for mop head frames. Keeping a few of these on hand can prevent down time in the manufacturing process. Contact the hardware manufacturer and request a list of the replacement parts available so they can be ordered if needed.

Mop hardware, including mop head frames, handles and buckets, should be inspected quarterly or biannually. Regularly scheduled cleaning and maintenance — removing chemical residues and replacing damaged or missing parts — will keep hardware in proper working order. Allocating time to complete these tasks will save time and money and adjustments such as bolt tightness in the long run by extending the life of the hardware.